Value Engineering: The Intuitive Approach for Perfection

Value engineering is a structured approach employed to enhance the value of a product or service through cost reduction and improved functionality. This method aims to boost the overall value of the offering while simultaneously cutting down expenses.

Value Engineering is a purposeful and systematic set of procedures to identify the best possible value for upfront and long-term investments. Originating in the manufacturing sector during World War II, this approach has been extensively applied in the construction industry.

Continuous refinement is the key to perfection. When one finishes a product, they often opine their job is done perfectly. However, there is always room for refinement. With changing times, one can always chip away and make a gem of a product. That is what value engineering, or VE, is all about.

Most organizations and entrepreneurs have realized that continuous improvement is the key to survival. And they have embraced value engineering in construction, which allows them to deliver quality products while reducing costs. The ingenious method which propels quality while reducing costs was first developed by GE executives.

They realized that cutting down on irrelevant components of a product would enhance its longevity and quality. The reduction of components thereby ensured quality and cost savings. But why is this approach in the limelight now?

Value Engineering (VE) goes beyond mere design review or cost-cutting exercises. It is an organized and imaginative endeavor that carefully assesses project requirements to achieve essential functions with the least total costs (including capital, staffing, energy, and maintenance) throughout its lifespan. Utilizing skilled and diverse teams, VE involves a comprehensive exploration of alternative design concepts, materials, and approaches, all while ensuring the client’s functional and value engineered objectives remain uncompromised.

What is Value Engineering?

Value engineering, or value analysis, is a structured and systematic approach to delivering essential project functions at a minimal cost. Encouraging the substitution of materials and methods with more economical alternatives ensures functionality remains intact without compromising quality. This engineering process focuses exclusively on evaluating the functions of components and materials rather than their physical characteristics.

Value engineering processes promote utilizing cost-effective alternative methods and materials that keep the functionality of the system, service, or product.

While value engineering typically occurs after the design engineering process, it is most effective before the design phase. This early approach enables experts to integrate the possibility of employing alternative materials and methods into the project.

In most value engineering in construction projects, a collaborative team approach is favored, bringing together subject matter experts to implement the value engineers methodology collectively.

Crucial Aspects

- Value engineering method is a systematic process used to improve the value engineers of a product or service by reducing costs and enhancing functionality.

- It seeks to achieve essential functions at the lowest total costs over the project’s life, considering capital, staffing, energy, and maintenance expenses.

- Value engineer involves a creative and organized effort, often conducted by experienced, multi-disciplinary teams.

- The focus is exploring alternative design concepts, materials, and methods without compromising the client’s functional and value objectives.

- It is also known as value analysis and encourages using cost-effective alternatives without sacrificing functionality.

- While typically conducted after the design process, value engineering method is most effective when performed before designing to integrate alternative options early on.

Also Read: A Guide to Tekton and Its Reusable Pipelines

Understanding the Relevance of VE

Ever since the pandemic set in, the world has undergone a paradigm change. Tried and tested formulae had to be rewritten. Businesses had to reinvent their successful strategies as the world was pushed into unknown circumstances. Although value engineering method is typically associated with the construction sector, software companies worldwide have imbibed this practice.

The systematic engineering process involves measuring the ‘value’ with swift and continuous feedback. Then, the amassed value engineered is harnessed to perfect the end-product.

This engineering values is essential as its deficiency triggers organizations to invest in frivolous projects that burn holes in their wallets. For instance, once Steve Jobs left Apple, the Macintosh manufacturer invested in many products that brought no value. One of the first things Jobs did when he returned to Apple was to kill most of them, and we all know how the company fared afterward.

History of Value Engineering

Value engineering originated in the 1940s at General Electric Co. during the Second World War, a period of scarcity in raw materials, parts, and skilled labor. To ensure uninterrupted production, engineers at General Electric had to innovate by seeking alternative components and raw materials. This necessity gave birth to the concept of value engineering processes.

Consequently, Lawrence Miles, Harry Erlicher, Jerry Leftow, and other engineers actively sought acceptable substitutes that could lower production costs while preserving the functionality of the products.

What began as an accidental discovery evolved into a structured process that decreased production costs and resulted in improved final products and enhanced performance. The engineers coined this technique “value analysis.”

Why Companies Should Adopt VE

According to a study accredited in “How to measure anything” book, 50% of product development is wasted on directionless front-end development, which is a futile investment. The ripple effects are harmful enough to stunt the company’s progress. From lean ROI to long, moribund feedback loops, the lousy product cycles often wind up becoming case studies on how not to develop a product.

This is unacceptable to any organization as today’s fast-moving world brooks no mediocrity. It is all the more reason why today’s companies should adopt value engineering processes. This perfectionist approach facilitates the company to dump its unwanted weight by tapping into the feedback loop.

How VE Ought to be Executed

One should not sacrifice quality while cutting costs. One should strive to offer affordable solutions, not produce cheap junk, which leaves a bitter aftertaste. Also, one should retain the product’s true essence in the ether. Affirming cost-cutting and quality assurance can be done by running trials or simulations.

However, before running these simulations, one should consider variables such as time to market, competition, and demand.

Additionally, when one completes the project, the team members often feel they could have gone the extra mile with certain aspects. This stage here is a great chance to introduce value engineering in construction. This creates a beautiful cycle where the team can initiate transformational activities which define new objectives.

The new objectives encourage the overall growth of the product. Based on the feedback, the amassed growth then fuels the transformational activities. It is a loop that ultimately keeps the product ticking.

Also Read: Measuring DevOps Success in 4 Ways!

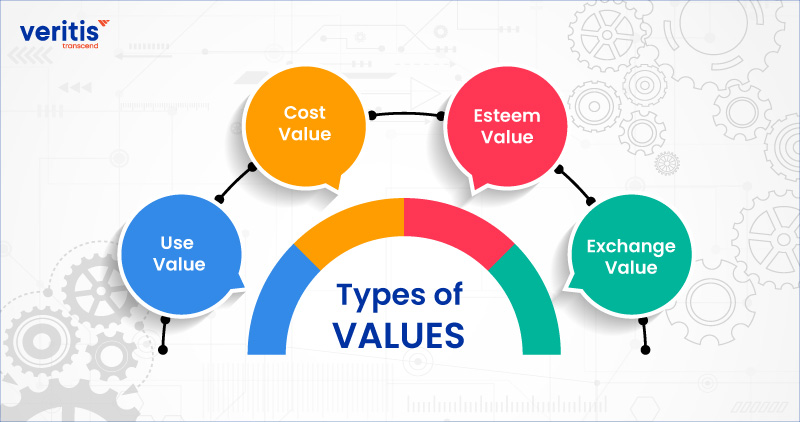

Types of Values

During value engineering, analysts frequently face defining ‘value.’ Customers may perceive the product differently, assigning varied worth to the goods. In general, value engineered recognizes four primary types of value.

1) Use Value

The primary value type is “use value,” which is determined by the product’s attributes. These attributes encompass the product’s functionality, usage, and purpose. Use value is closely linked to product differentiation, as consumers can uniquely derive value from a specific product that differentiates them from competitors.

The foremost objective of value engineer is to ensure the use value of a product. Use value is vital because it drives consumers to make initial purchases. For example, if a particular type of shoe fails to adequately protect someone’s feet or enable them to walk comfortably, it lacks significant use value. Without the use of the value engineers, products are bound to fail as they serve no meaningful purpose to consumers.

2) Cost Value

Having established that the shoes possess significant use value, the next consideration is the production process. Since these shoes are designed for hiking, rugged wear, and waterproof protection, their crafting may necessitate skilled labor, specifically-treated raw materials, and stringent quality control measures to ensure consumer safety.

The abovementioned variables represent different cost factors with distinct values in this example. While a consumer may perceive the shoes’ value at USD 50 per pair, the company must evaluate its cost value, which might be USD 75 per pair. The company must assess how to reconcile these differences to achieve a balanced equation. Charging customers excessively high prices would likely result in a negative cost value.

3) Esteem Value

In addition to the use value, consumers may perceive intrinsic value in a product, which goes beyond its physical benefits. For instance, if the shoe mentioned above is a Nike product, consumers might be willing to pay a higher premium due to its added prestige and brand recognition.

While esteem value is typically positive and linked to brand recognition, it can also be harmful and tied to brand dissonance, depending on the product’s target consumer. For instance, budget-conscious consumers who prioritize affordability may perceive negative esteem value when considering Apple’s innovative, higher-cost product line.

4) Exchange Value

The final and smallest aspect of value pertains to a product’s exchangeability. Thanks to international shipping and supply chain analytics advancements, it has become increasingly convenient for almost any consumer to receive products within a reasonable timeframe.

A value engineer must consider how to facilitate the distribution of a product, along with its physical characteristics and other attributes that enable easy purchasing or trading. The value may be lost or compromised if consumers encounter significant difficulties buying or receiving the product.

Also Read: DevOps for AI: Make AI Operationalization a Core Business Objective!

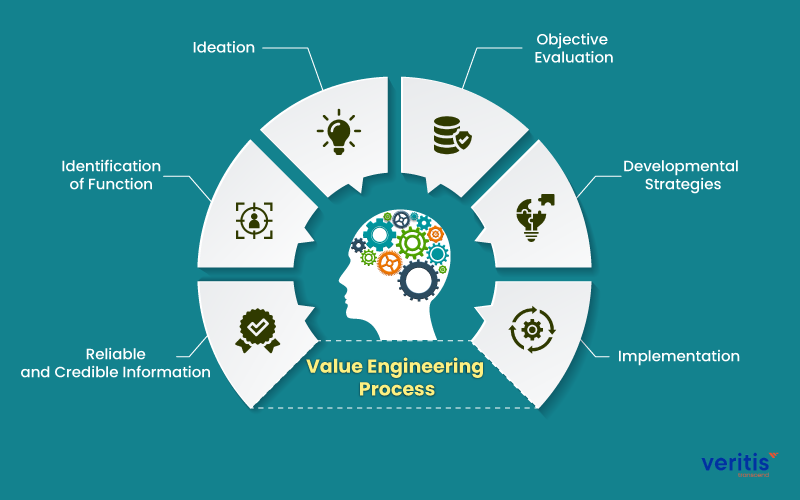

Value Engineering Process

Given how vital it is to be ahead of the competition, it is imperative that one ought to follow specific steps to achieve optimal results. Let’s see what those steps are.

1) Reliable and Credible Information

In this advanced age, information is everything. Organizations should make ‘information gathering’ part of the value engineering strategy, as information brings value. The collected data should be analyzed and gleaned insights become the cornerstone for the refinement.

The organization should truncate the information into actionable components, which become the ingredients for improvement. At this stage, one should ideate how to improve the existing solution. And you should also bring forth an evaluation value engineering process to assess the health and progress of the project.

2) Identification of Function

It is understandable to need clarification on the overabundance of information streaming through value engineering. The underlying function should label the actionable insights to avoid snafus and faux pas.

For instance, if one has encountered a malfunctioning code, one can label it as ‘rectify code’ and use it for communication. The prefix denotes what needs to be done, and based on these functions, the organization can arrive at a cost estimate. With the work segregated and cost estimates in hand, the company can consider the following aspect.

3) Ideation

There is always a better way to do things. If one suggests such an approach that supports the engineering values criterion (a better quality that lowers expenses), one ought to go with that suggested approach.

However, to elicit such ideas, the organization should encourage brainstorming sessions. Be it creative arguments or better logic, one shall certainly elicit relevant ideas.

Additionally, the brainstorming sessions’ agenda should establish the functionality objectives. The actionable prefix reminds the team members of what needs to be achieved.

4) Objective Evaluation

Trimming the unwanted weight significantly is challenging since the organization helped create the product. Various vestigial elements in the software will bog down the product and increase operational overheads. Once the information is understood, and post-identification of functions and acting upon the insights, one must critically examine the actions from a larger perspective.

The company can determine the product’s future by pitting the pros against the cons of any component or idea that arose from the previous aspects. If the cons pummel the pros, the company should terminate the proposed idea and propose an alternative. The company should subject the alternative to the same drill.

5) Developmental Strategies

An idea needs to be built on a sound foundation. Once a bright idea emerges, the team should embark on research and do an in-depth analysis of every alternative that has been shortlisted. The expected developmental costs should firm up in these discussions. The team should then proceed with the approvals.

6) Implementation

After getting the due approvals from all, please don’t alter the plan unless required. If a change is required, one should keep everyone in the loop and get approvals from the hierarchical superiors. Moreover, the team should always respect the principles of engineering values. If the strategy is not aligning with the principles, revert to the previous step and start developing a new strategy.

Also Read: Continuous Integration: The DevOps Approach Which Fuels Productivity

In Conclusion

Companies across the globe are firing on all cylinders to stay relevant. However, time and again, corporate history has proven that giants will fall if they don’t appreciate the change that time brings along. Innovation is fueled only when the companies are bold enough to ax the components they helped create.

In simpler terms, the DevOps team of the company should prepare to modify the software as per the changing hardware and needs. The change will be the key to staying relevant, and value engineering is one of the most productive approaches that will lead you there.

Having catered to the needs of various companies, Veritis, the Stevie Award Winner, left no stone unturned in helping the clients stay ahead of the times. From development to deployment to maintenance, the in-house experts of Veritis keep chipping until the clients are strong-armed with a robust and relevant solution. So, contact us and let us engineer some value into your promising products!

Got Questions? Schedule A Call

Also Read:

- 6 Ways AIOps Optimizes Cloud Security

- AI-Powered, ML-Driven – The New DevOps Trend!

- The Role of Artificial Intelligence in Business: Opportunities, Challenges, and Best Practices for CEOs and CTOs

- Understanding XaaS: Everything as a Service and its Advantages

- Anomaly Detection with MI & AI : An Introduction

- All You Need to Know about Artificial Intelligence as a Service (AIaaS)