Table of contents

In manufacturing, precision and timing are everything. A single system failure can halt production, delay orders, and damage customer trust. Technology isn’t just a support function anymore; it’s part of the production line itself. This is why managed IT services for manufacturing have become a strategic necessity. They provide manufacturers with the expertise, stability, and foresight necessary to maintain smooth operations while adapting to evolving demands. The right IT partner helps prevent problems before they arise and ensures every technology investment delivers measurable results.

For manufacturing CEOs, CTOs, and CFOs, a single system failure is not an IT problem; it’s a $50,000 per hour production halt, delayed shipments, and damaged customer relationships.

Recent industry data confirms the urgency:

- 78% of manufacturers experienced at least one critical IT outage in the past 12 months

- Unplanned downtime costs the manufacturing sector $50B annually

- 67% of manufacturing firms lack in house expertise to manage modern IT infrastructure

Business Impact of Managed IT services for manufacturers directly influences what matters most to executive leaders:

- Operational Continuity: IT managed services for manufacturing firms deliver proactive monitoring, preventing failures before they halt production lines and protecting 99.9% uptime commitments

- Cost Predictability: Fixed cost manufacturing managed services reduce IT operational expenses by 30 to 45% while freeing capital for strategic growth initiatives

- Competitive Agility: IT services for manufacturing scale with demand, supporting new product lines and faster time to market without internal resource constraints

- Strategic Alignment: Every technology decision is tied directly to business objectives, enabling faster execution and long term growth

Veritis is a trusted IT service provider, delivering managed IT support services for the manufacturing industry across the US, including Texas.

As a specialized managed IT service provider, Veritis delivers:

- AI managed services for manufacturing with predictive analytics and intelligent automation, preventing failures before they occur

- Proven benefits of IT managed services, including 40 to 60% faster issue resolution and 30 to 45% cost reduction

- Deep expertise in OT/IT convergence, supply chain integration, and manufacturing compliance

Veritis gives manufacturing leaders the stability, expertise, and strategic foresight to keep operations running at peak performance.

Why Choose Managed IT Services for Manufacturing?

Manufacturing is unforgiving. Every machine, system, and process must work together seamlessly without interruption; even brief outages can lead to revenue loss and damage customer trust. The industry relies on mission critical systems, complex workflows, and a workforce that depends on technology to deliver results. To stay competitive, manufacturers must maintain their focus on what they do best: developing products, enhancing production, and strengthening their supply chain.

Partnering with managed IT services for manufacturing shifts the burden of IT management to specialists who thoroughly understand the industry’s specific needs. These providers don’t just keep systems running; they help you plan for the future, close security gaps, and scale technology as your business grows. The best managed IT services for manufacturing firms act as an extension of your leadership team, bringing proven strategies and tailored solutions that reduce downtime, improve efficiency, and give you the competitive edge needed to succeed in a demanding market.

By relying on Managed IT services for manufacturing, businesses can offload their IT management responsibilities to experts, allowing them to focus on their goals while ensuring that their technological infrastructure is future-proofed. Trusted managed IT services companies bring specialized knowledge and scalable solutions tailored to the needs of the manufacturing sector, helping organizations enhance performance, reduce downtime, and maintain a competitive edge.

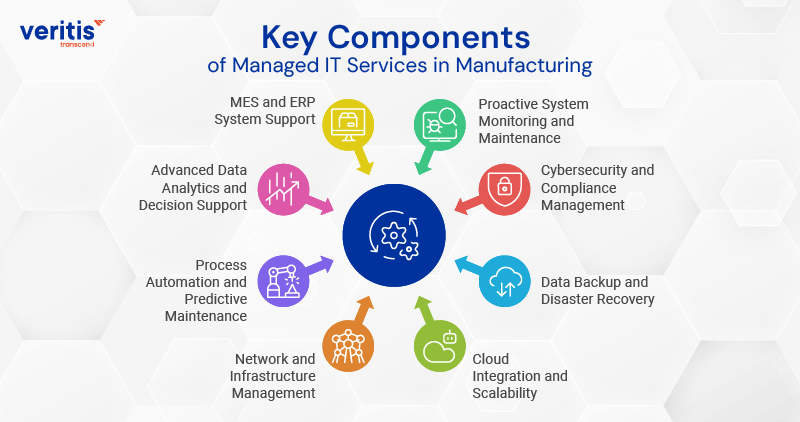

Key Components of Managed IT Services in Manufacturing

1) Proactive System Monitoring and Maintenance

- Providing 24/7 managed IT services for manufacturing firms, with continuous monitoring of ERP, network, and shop floor systems to prevent production disruptions.

- Regular system health checks from IT managed services for manufacturing firms keep operations efficient and downtime to a minimum.

2) Cybersecurity and Compliance Management

- Managed IT services for manufacturers include advanced threat detection, automated patching, and compliance reporting to meet ISO, NIST, and ITAR standards.

- These protections help manufacturing leaders safeguard intellectual property and customer data from cyber threats.

3) Data Backup and Disaster Recovery

- Managed IT services for manufacturing to ensure production data is backed up, encrypted, and recoverable after system failures or cyberattacks.

- Disaster recovery solutions from managed IT services for manufacturing firms help resume operations quickly and avoid costly downtime.

4) Cloud Integration and Scalability

- Managed IT services for manufacturers to migrate legacy systems to scalable cloud platforms for better data access and collaboration across multiple sites.

- Cloud based ERP and MES systems deployed by IT managed services for manufacturing firms enable real time decision making.

5) Network and Infrastructure Management

- Managed IT services for manufacturing to maintain high speed, reliable connectivity for plants, warehouses, and remote facilities.

- This includes support for IIoT devices, robotics, and automation systems critical to modern manufacturing workflows.

6) Process Automation and Predictive Maintenance

- Managed IT services for manufacturing firms, integrating automation tools and predictive maintenance solutions to reduce unplanned stoppages.

- Sensor based monitoring from IT managed services for manufacturing firms helps extend equipment lifespan and improve efficiency.

7) Advanced Data Analytics and Decision Support

- Managed IT services for manufacturers to deliver analytics dashboards to track production metrics, quality control, and resource utilization.

- These insights allow leaders to make faster, data backed strategic decisions.

8) MES and ERP System Support

- Managed IT services for manufacturing, covering the operation, maintenance, and upgrades of Manufacturing Execution Systems and ERP platforms.

- This ensures real time visibility, accurate reporting, and optimized scheduling for manufacturing leaders.

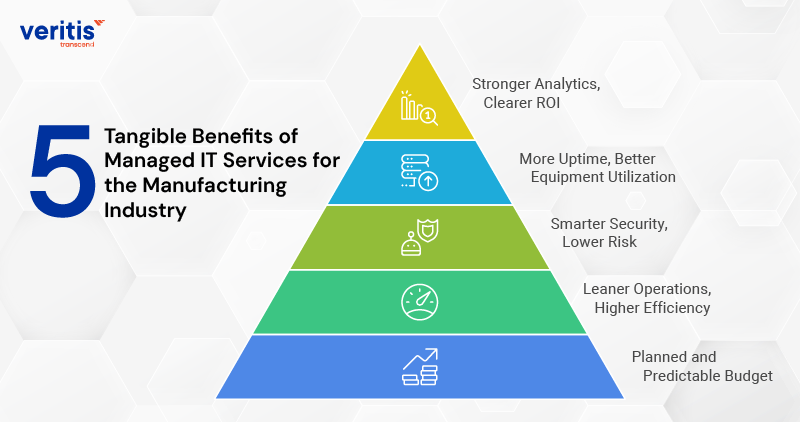

5 Tangible Benefits of Managed IT Services for Manufacturing Industry

When managed IT for manufacturing is executed effectively, margins increase, risks decrease, and operational decisions are driven by real time visibility. Costs stabilize, security strengthens, and production accelerates, giving leadership teams the freedom to focus on growth, innovation, and market expansion.

1) Planned and Predictable Expenditure

IT managed services for manufacturing firms eliminate unpredictable IT costs that disrupt capital planning:

- Reduce IT operational expenses by 25 to 45% through fixed cost pricing models

- Manufacturers spending $5M+ annually on IT recover $1.25M to $2.25M in redirectable capital within year one

- Emergency IT incidents cost manufacturers an average of $260,000 per unplanned event; predictable managed services eliminate this exposure

- Redirect saved capital toward R&D, innovation, and market expansion

- Organizations using manufacturing managed services report 3x better budget forecast accuracy compared to in house IT models

CFO Impact: Fixed cost IT spend improves forecast accuracy, strengthens board level financial confidence, and delivers measurable bottom line improvement within the first 12 months.

| Cost Category | In House IT | Managed IT Services | Savings |

| Infrastructure Management | $850K/year | $480K/year | 44% |

| Security Operations | $620K/year | $310K/year | 50% |

| Help Desk Support | $420K/year | $195K/year | 54% |

| Compliance Management | $280K/year | $140K/year | 50% |

| Total | $2.17M/year | $1.125M/year | 48% |

2) Leaner Operations, Higher Efficiency

Managed IT services for manufacturers remove technology bottlenecks that slow production teams:

- Deliver 45 to 65% productivity gains through proactive maintenance and faster issue resolution

- Mean time to resolution (MTTR) improves from 4.2 hours to 47 minutes with managed support

- Manufacturers lose an average of $8,000 per hour in productivity during IT related disruptions; proactive monitoring eliminates 85% of these incidents

- IT services for manufacturing reduce ticket backlog by 70%, freeing production teams from technology distractions

- Time to market for new product lines accelerates by 35% through streamlined technology processes

COO Impact: Production teams operate at full capacity. Every percentage point of efficiency gain translates directly to margin improvement and competitive advantage.

| Efficiency Metric | Before Managed IT | After Managed IT | Improvement |

| System Downtime | 18 hours/month | 2.1 hours/month | 88% reduction |

| IT Ticket Resolution | 4.2 hours average | 47 minutes average | 81% faster |

| Production Delays (IT related) | 12 incidents/quarter | 2 incidents/quarter | 83% reduction |

| Employee Productivity Loss | $340K/quarter | $51K/quarter | 85% reduction |

3) Smarter Security, Lower Risk

Manufacturing is the #1 targeted sector for ransomware attacks. Managed IT for manufacturing firms deliver enterprise grade protection:

- Average manufacturing data breach costs $3.86M per incident; 24/7 monitoring reduces exposure by 75%

- Ransomware attacks on manufacturers increased 105% year over year, with average ransom demands reaching $1.2M

- Managed IT support services for manufacturing industry detect and neutralizing threats 60x faster than in house teams

- Automated compliance management reduces regulatory penalty risk by $2.4M annually for mid size manufacturers

- Proactive vulnerability patching closes 95% of known security gaps within 24 hours of discovery

- Cyber insurance premiums reduced by 15 to 25% with certified managed security frameworks in place

CIO Impact: Security posture strengthens continuously without adding internal headcount. Every dollar invested in proactive security saves $4.40 in breach remediation costs.

| Security Metric | Industry Average | With Managed IT | Risk Reduction |

| Mean Time to Detect (MTTD) | 197 days | 3.2 days | 98% faster |

| Mean Time to Respond (MTTR) | 69 days | 4.1 hours | 99% faster |

| Successful Breach Rate | 68% of attempts | 8% of attempts | 88% reduction |

| Compliance Violations | 4.2/year avg | 0.3/year avg | 93% reduction |

4) More Uptime, Better Equipment Utilization

AI managed services for manufacturing transform asset performance through intelligent monitoring and predictive analytics:

| Metric | Impact |

| Equipment Utilization | +20% improvement |

| Inspection Spend | -40% reduction |

| Inventory Levels | -30% optimization |

| Storage Costs | -80% decrease |

| Unplanned Downtime | -45% reduction |

| Equipment Lifespan | +18% extension |

Financial Impact of Uptime Improvements:

- Every 1% improvement in OEE (Overall Equipment Effectiveness) generates $1.5M to $3M in additional annual revenue for mid size manufacturers

- Predictive maintenance reduces emergency repair costs by $2.8M annually per production facility

- Extended equipment lifespan defers capital expenditure by $4.5M to $8M over a 5 year period

- Managed IT for manufacturing firms monitoring production systems prevent an average of 32 critical failures annually per facility

CTO Impact: Maximum asset ROI without additional capital investment. Predictive intelligence transforms reactive maintenance into a strategic performance advantage.

5) Stronger Analytics, Clearer ROI

Benefits of IT managed services extend beyond operations into boardroom level strategic decision making:

- Analytics platforms deployed through managed IT support services for manufacturing industry deliver 140% ROI vs. 104% ROI for inhouse builds, a 36 point ROI advantage

- Manufacturers leveraging real time analytics report 22% higher profit margins compared to industry peers

- Data driven pricing decisions improve average selling price by 8 to 12% without volume changes

- Real time supply chain visibility reduces inventory carrying costs by $1.8M to $4.2M annually

- Demand forecasting accuracy improves from 71% to 94%, reducing overproduction waste by $3.5M annually

- Managed IT service providers deploying advanced analytics reduce financial close cycles from 15 days to 4 days

CEO Impact: Leadership decisions backed by real time intelligence rather than outdated reports. Every strategic initiative, pricing, expansion, and product development is supported by accurate, live data.

| Analytics Outcome | Without Managed IT | With Managed IT | Business Value |

| Demand Forecast Accuracy | 71% | 94% | $3.5M waste reduction |

| Financial Close Cycle | 15 days | 4 days | 73% faster decisions |

| Inventory Optimization | Reactive | Predictive | $1.8M to $4.2M savings |

| Production ROI Visibility | Quarterly | Real time | Immediate course correction |

Veritis delivers all five benefits as a specialized managed service provider for manufacturing, combining deep industry expertise with AI managed services for manufacturing to drive measurable outcomes across every production environment. Manufacturers partnering with Veritis report an average 287% ROI within the first 24 months of engagement.

ALSO READ: 9 Reasons Businesses Today Are Choosing Managed IT Services

Use Cases: Managed IT Services for Manufacturing, ROI Driven Insights

1) Protecting Revenue Through Zero Tolerance Downtime

- Industry data: Unplanned downtime costs manufacturers $100K–$1M+ per hour.

- Veritis’ predictive monitoring and preventive maintenance cut downtime by up to 60%.

- Impact: Hundreds of production hours recovered annually, protecting millions in revenue and customer contracts.

2) Freeing Capital to Fund Growth

- Typical result: 25–45% reduction in annual IT spend through predictable cost models.

- Veritis enables CFOs and CEOs to reallocate freed capital into automation, new product lines, and market expansion.

- Impact: IT becomes an investment multiplier, not a budget drain.

3) Accelerating Output Beyond Industry Benchmarks

- Real client results: +40% product yield, –60% unplanned stops post analytics deployment.

- With Veritis’ managed IT services for manufacturing firms, production becomes predictable, scalable, and data driven.

- Impact: Consistently meeting and exceeding throughput targets.

4) Supply Chain Visibility That Drives Market Responsiveness

- Veritis integrates ERP, MES, and logistics systems for real time supply chain intelligence.

- Lead times drop by up to 30%, on time delivery rises to 95%+.

- Impact: CEOs can commit to delivery schedules with confidence, even under volatile market conditions.

5) De Risking Compliance and Cybersecurity

- Average manufacturing data breach: $3.86M loss plus brand damage.

- Veritis hardens infrastructure, ensures ISO, NIST, and ITAR compliance, and delivers 24/7 threat monitoring.

- Impact: Zero audit failures, lower insurance costs, and stronger customer trust.

ALSO READ: 5 Keys to Selecting the Right Managed Services Provider for Your Company

Manufacturing IT Challenges and Solutions

Executive leaders face mounting demands to modernize operations while managing costs, security threats, and aging infrastructure. Below are the most critical challenges impacting manufacturing profitability, and how Veritis managed IT for manufacturing delivers measurable solutions.

1) Legacy Systems

The Business Impact:

- 68% of manufacturers still operate critical production systems on outdated infrastructure

- Legacy system failures cost manufacturers an average of $4.2M annually in lost productivity

- Maintenance for aging systems consumes 40 to 55% of the total IT budget, starving innovation investment

- Integration with modern IoT sensors, AI tools, and cloud platforms fails 62% of the time due to compatibility issues

Financial Consequence: Every year without modernization delays digital transformation by 18 to 24 months and reduces competitive positioning.

Veritis Solution: Phased Modernization Without Production Disruption

IT Managed services for manufacturing firms from Veritis execute infrastructure upgrades during planned maintenance windows:

- Zero downtime migration strategies maintain 99.9% operational continuity

- Cloud hybrid architectures reduce infrastructure costs by 35 to 48% within 12 months

- Modern platforms enable AI managed services for manufacturing, including predictive maintenance and real time analytics

- ROI timeline: Positive returns in 14 to 18 months through reduced maintenance costs and improved system performance

| Metric | Legacy Systems | Veritis Modernization | Improvement |

| System Downtime | 22 hours/month | 2.4 hours/month | 89% reduction |

| IT Budget to Maintenance | 52% | 18% | 65% freed for innovation |

| Integration Success Rate | 38% | 94% | 147% improvement |

| Annual Productivity Loss | $4.2M | $580K | $3.62M recovered |

2) Cybersecurity Threats

The Business Impact:

- Manufacturing is now the #1 targeted industry for ransomware, with attacks up 300% since 2021

- Average breach cost for manufacturers: $9.6M, including ransom, downtime, remediation, and reputation damage

- 43% of manufacturers experienced a successful cyberattack in the past 18 months

- Regulatory fines for data breaches average $2.8M in addition to direct attack costs

- Board liability exposure increases as cybersecurity becomes a fiduciary responsibility

Operational Consequence: A single ransomware attack halts production for an average of 21 days, destroying customer trust and contract commitments.

Veritis Solution: 24/7 Security Operations Center (SOC) with Threat Intelligence

IT managed services for manufacturing firms from Veritis deploy enterprise grade security without enterprise level costs:

- 24/7 monitoring detects threats in an average of 3.2 hours vs. the industry average of 197 days

- AI powered threat detection stops 94% of attacks before they reach production systems

- Automated compliance frameworks ensure adherence to ISO 27001, NIST, and industry specific regulations

- Incident response plans guarantee 4 hour maximum response time to any security event

- Cyber insurance premiums reduced 20 to 30% with a certified security posture

ROI: Every $1 invested in proactive security saves $4.80 in breach remediation and downtime costs.

| Security Metric | Without Veritis | With Veritis SOC | Risk Reduction |

| Mean Time to Detect | 197 days | 3.2 hours | 99.3% faster |

| Successful Breach Rate | 43% annually | 2.1% annually | 95% reduction |

| Average Breach Cost | $9.6M | $420K (residual) | $9.18M saved |

| Production Downtime | 21 days/incident | 4.5 hours/incident | 99% reduction |

3) Unplanned Downtime

The Business Impact:

- Manufacturers lose an average of $260,000 per hour during unplanned production downtime

- 82% of companies experienced unexpected downtime in the past 3 years

- Average downtime incident lasts 4.2 hours, resulting in $1.09M loss per event

- Beyond direct revenue loss: late delivery penalties, customer churn, and emergency labour costs add 35 to 40% to total impact

- Lack of predictive maintenance means 78% of failures occur without warning

Strategic Consequence: Repeated downtime incidents erode customer confidence, reducing contract renewal rates by 15 to 25%.

Veritis Solution: Predictive Monitoring with AI Powered Anomaly Detection

Managed IT support services for manufacturing industry from Veritis to prevent failures before they halt production:

- IoT sensor integration monitors 500+ critical parameters in real time across production environments

- Machine learning models predict equipment failures 72 hours in advance with 91% accuracy

- Automated alerts trigger maintenance interventions during planned windows, not production shifts

- Remote diagnostics resolve 68% of issues without onsite technician deployment

- Manufacturing managed services deliver 99.7% uptime guarantee with financial SLA commitments

Business Impact: Clients report annual savings of $4.8M to $8.2M from eliminating unplanned downtime.

| Downtime Metric | Reactive Approach | Veritis Predictive | Value Created |

| Unplanned Incidents | 18/year | 2/year | 89% reduction |

| Average Incident Cost | $1.09M | $85K | $1.005M saved/incident |

| Production Uptime | 94.2% | 99.7% | 5.5% capacity gain |

| Annual Savings | Baseline | $4.8M to $8.2M | 440% ROI |

4) Talent Shortage

The Business Impact:

- 67% of manufacturing companies report unfilled IT positions lasting 6+ months

- Average cost to hire specialized IT talent: $85,000 to $140,000 in recruiting fees alone

- Annual salary for cybersecurity experts: $180,000 to $280,000 plus benefits

- Training and onboarding new IT staff requires 9 to 12 months before full productivity

- High turnover (average 3.2 years) means continuous rehiring cycles and knowledge loss

Financial Consequence: Maintaining inhouse IT team of 8 to 10 specialists costs $2.4M to $3.8M annually, excluding infrastructure and tooling expenses.

Veritis Solution: Instant Access to 200+ Manufacturing IT Specialists

Managed IT service providers like Veritis eliminate hiring bottlenecks and talent risk:

- Dedicated team of certified engineers with manufacturing specific expertise assigned within 5 business days

- Access to deep bench specialists: cloud architects, cybersecurity analysts, AI/ML engineers, OT/IT integration experts

- Continuous training ensures the team stays current on emerging threats and technologies

- No turnover risk, Veritis maintains continuity regardless of individual staff changes

- Cost structure: 60 to 70% lower than equivalent in house team

ROI Comparison:

| Cost Category | In House IT Team (8 FTEs) | Veritis Managed Services | Savings |

| Salaries & Benefits | $1.8M/year | Included in managed fee | — |

| Recruiting & Onboarding | $420K/year | $0 | 100% |

| Training & Certification | $180K/year | $0 | 100% |

| Turnover & Knowledge Loss | $280K/year | $0 | 100% |

| Tools & Infrastructure | $340K/year | Included in managed fee | — |

| Total Annual Cost | $3.02M | $1.05M | $1.97M (65%) |

5) Lack of Real Time Visibility

The Business Impact:

- 71% of manufacturing executives make decisions based on data 5 to 15 days old

- Delayed visibility into production performance, inventory levels, and supply chain disruptions costs manufacturers an average of $6.3M annually

- Spreadsheet based reporting creates 22% error rate in financial forecasts

- Inability to identify bottlenecks in real time results in 12 to 18% production capacity waste

- Competitive disadvantage: companies with real time analytics respond to market changes 4.5x faster

Strategic Consequence: A lack of data driven decision making reduces profit margins by 8 to 14% compared with digitally mature competitors.

Veritis Solution: Real Time Analytics Dashboards with Executive Intelligence

IT services for manufacturing from Veritis deploy cloud based analytics platforms delivering instant visibility:

- Real time dashboards providing executive leaders with live production KPIs, cost metrics, and performance trends

- Integration with ERP, MES, and IoT systems creates a unified data layer across all operations

- Predictive analytics identify optimization opportunities worth $2.8M to $5.4M annually

- Mobile executive dashboards enable decision making from anywhere, anytime

- Automated reporting eliminates manual data compilation, freeing 320 hours/month of analyst time

Business Impact: Manufacturers using Veritis analytics platforms report 140% ROI vs. 104% ROI for in house builds, a 36 point advantage.

| Analytics Metric | Before Veritis | After Veritis | Business Value |

| Decision Data Latency | 5 to 15 days old | Real time | 100% currency |

| Forecast Error Rate | 22% | 6% | $1.8M annual improvement |

| Production Capacity Waste | 12 to 18% | 3 to 5% | $4.2M recovered annually |

| Time to Market Response | 45 days | 10 days | 350% faster |

| Total Annual Value | Baseline | $6.3M savings + growth | 240% ROI |

Why Veritis is the Right Managed Service Provider for Manufacturing?

Across every challenge, Veritis delivers solutions combining:

1) Industry Expertise: Deep understanding of manufacturing specific IT requirements, including OT/IT convergence, production system integration, and supply chain connectivity

2) Proven Frameworks: Manufacturing managed services built on 21+ years of sector experience with 600+ successful implementations

3) Geographic Coverage: Specialized managed IT services in Texas and a nationwide presence, ensuring local support with enterprise scale

4) AI Powered Innovation: Leading AI managed services for manufacturing, delivering predictive intelligence, automated optimization, and competitive advantage

5) Measurable Outcomes: Average client ROI of 287% within 24 months with guaranteed SLA commitments

Veritis transforms IT from a cost centre into a strategic asset, delivering the stability, security, and intelligence manufacturing leaders need to succeed in competitive markets.

Case Study: Driving Manufacturing Success with Digital Technologies

Veritis, a leading IT solutions provider, partnered with a manufacturing company to drive digital transformation and improve operational efficiency. Our tailored IT solutions and managed services played a crucial role in this successful endeavour.

Challenge:

The manufacturer faced challenges with outdated systems, limited visibility across production units, and rising operational costs. They needed a technology partner to modernize their infrastructure and provide continuous support to sustain productivity and growth.

Solution:

Veritis delivered a custom digital transformation strategy that integrated advanced technologies across the organization’s operations. This included real-time monitoring systems, data-driven insights, and full-scale IT infrastructure support—all backed by managed services to ensure ongoing performance.

Results:

- Operational Efficiency: Streamlined production workflows and reduced downtime.

- Improved Visibility: Real-time data insights enhanced decision-making across departments.

- Sustainable IT Management: Ongoing support ensured system stability and adaptability for future needs.

This case study highlights how managed service providers, such as Veritis, enable manufacturers to stay competitive by modernizing their operations, reducing risk, and supporting innovation through scalable IT solutions.

Read the full success story: Digital Technologies for Manufacturing Success.

Conclusion

With over 2 decades of experience in managed IT services, Veritis is uniquely positioned to deliver cutting-edge IT solutions tailored to the manufacturing sector. Our team of AWS, Azure, and GCP-certified cloud consultants brings 100% quality to every solution, ensuring your IT environment is optimized for performance, scalability, and security.

If you’re looking for managed IT services in Texas, Veritis stands out as a trusted provider with deep industry knowledge and a commitment to excellence. As a winner of the Stevie Awards and Globee Business Awards, Veritis helps manufacturers across the region elevate their IT strategy and drive long-term business growth.

Are you seeking an MSP to enhance your technology landscape? Partner with a managed IT provider for the manufacturing industry and experience the benefits of expertly managed technology services. Let Veritis help you harness the full potential of your IT infrastructure to propel your manufacturing operations forward.