The ability to build a collaborative culture makes DevOps the most sought-after IT practice for every industry, regardless of size.

Alongside core technology firms, DevOps is growing in popularity among industrial processes, especially in the manufacturing sector. DevOps suits the manufacturing sector more, considering the industry’s busy process chain running around the clock.

DevOps is gaining traction as a vital IT practice across industries of various sizes and types, ranging from startups to established technology firms and manufacturing plants. The continuous activity in manufacturing production chains makes DevOps strategies particularly suitable for this sector.

The market’s demand for swift expansion, rapid delivery, and innovation-driven progress necessitates a different approach to manufacturing chains, hence the growing need for DevOps within this industry.

DevOps, characterized by automation, collaboration, and communication, is an approach to software development. Initially linked with software companies, it is now increasingly embraced by manufacturing firms aiming for operational excellence.

Moreover, the market’s run for rapid expansion, faster delivery, and fueled innovation demands an all-new approach in the manufacturing chain, driving the demand for DevOps adoption in the manufacturing sector.

How Important is DevOps in Manufacturing?

Streamlined communication and increased collaboration define DevOps significance in the manufacturing sector.

Success through DevOps means achieving robustness in three core areas, namely:

- Collaboration

- Automation

- Innovation

Together, these three areas result in increased communication and seamless flow among teams, resulting in faster delivery and reduced time to market.

Let’s look into each of the three core areas in detail!

1) Collaboration

The most common challenge many firms face is the ‘lack of collaboration’ among the internal teams. More than a process, this is a culture that many are looking for but cannot easily achieve. This is where DevOps plays a crucial role by bringing together the Development and Operations teams.

Saying goodbye to the siloed approach, DevOps bridged gaps between Dev and Ops teams, making them aware of each other’s tasks. This results in quality checks at every step and necessary testing, making the product ready at the end of the process chain. All this means a strong collaboration.

Useful Link: How DevOps Automation Works?

2) Automation

This is one word that’s wrongly understood by many ‘as a machine-based replacement to the human workforce.’ But it’s not entirely. DevOps automation tools, by definition, mean applying automated

solutions for time-consuming tasks. Considering the level of automation already in modern manufacturing processes, achieving robustness in this area means a lot for any manufacturer. And DevOps methodologies can help you!

3) Innovation

Assured quality and production results naturally minimize the majority of pressure coming from the product development life cycle, thus leaving space for innovation. Innovation is significant in giving you a competitive edge in the market. DevOps methodologies give you all possible ways to drive innovation. By minimizing the time taken for process execution, DevOps lets business decision-makers think of new ideas by handing over the existing processes to internal teams.

The Benefits of DevOps in Manufacturing Sector

For the last century, manufacturing companies have focused on perfecting the process of mass production. In recent years, the emergence of technologies has pushed the manufacturing sector to rethink its business models, systems, and services. DevOps is one such technology that has enabled companies to transform their operations from production efficiency to product customization while improving speed to market, service effectiveness, and creation of new business models.

DevOps brings along a host of benefits to manufacturing companies, including:

- Greater visibility into daily activities

- Transparency across the manufacturing processes

- Real-time data insights

- Quick identification and redressal of performance issues

- Empower cross-functional teams to focus on a common objective

- Actionable insights on customers, product design, and supply chain

- End-to-end accountability

- Streamline and automate internal processes

- Foster shared common goals

- Enhance collaboration

- Minimum waste, maximum efficiency, greater productivity

Useful Link: Transforming Manufacturing With Cutting-edge Technology

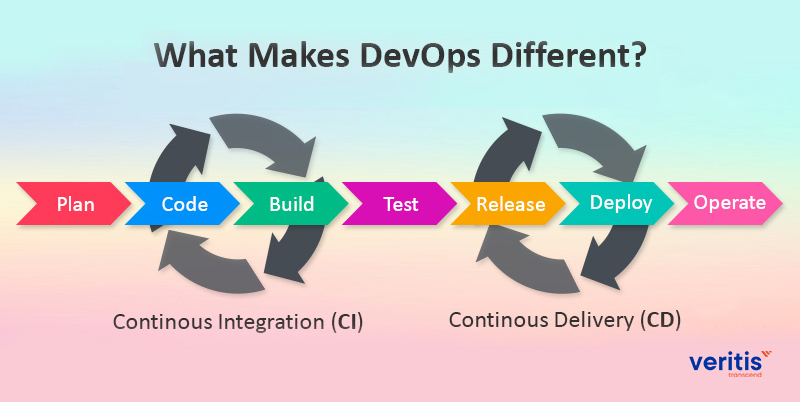

What Makes DevOps Different?

DevOps’s key difference from the traditional software development model lies in its dealing with code.

DevOps’ approach to software lifecycle is based on its core concepts: Continuous Delivery and Continuous Integration (CI/CD cycle).

In the traditional approach, multiple developers work on various components of an application and finally merge the code at the end. Here, bugs in the code demand a complete rework. This naturally causes delays in bug detection and manual integration.

DevOps makes a big difference with its CI/CD cycle by allowing developers to deliver code updates faster and more frequently into a shared repository like GIT.

In doing so, each developer will check the code in small units, followed by regular compilation. The automated build (including testing, security, UI, etc.) checks every piece of code as it moves into the repository. This naturally results in early bug detection and faster recovery, thus increasing developer productivity.

Releases from the CI phase are automatically fed into the release pipeline, where functions like copying files, stopping, and resuming services are performed. Deployments are also handled, leading to Continuous Delivery.

In a nutshell, the CI/CD pipeline is the heart of DevOps’ success!

Useful Link: Continuous Integration: The DevOps Approach Which Fuels Productivity

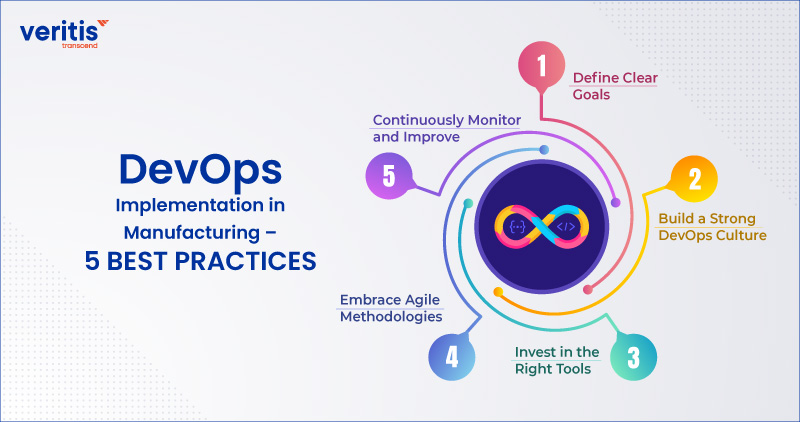

DevOps Implementation in Manufacturing – 5 Best Practices

Implementing DevOps in manufacturing is gaining momentum, although it’s still nascent. Many manufacturers are turning to DevOps to remain competitive in an evolving industry landscape. However, challenges persist, with cultural change being a significant hurdle. Shifting from traditional, siloed software development to a collaborative, integrated approach requires a fundamental mindset change, which can be challenging for some organizations.

A strategic approach is essential to effectively implementing DevOps in manufacturing. Here are five best practices for DevOps teams to consider:

1) Define Clear Goals

Start with a clear understanding of your goals. What do you hope to achieve with DevOps? What are your priorities?

2) Build a Strong DevOps Culture

Encourage collaboration, communication, and a focus on continuous improvement to foster a strong DevOps culture.

3) Invest in the Right Tools

Choose DevOps automation tools, testing tools, and other software products tailored to the manufacturing industry’s needs.

4) Embrace Agile Methodologies

Utilize Agile methodologies like Scrum and Kanban to streamline software development and deployment processes.

5) Continuously Monitor and Improve

Use metrics and analytics to monitor your progress and detect areas for improvement in your DevOps practices.

Key Takeaways:

- DevOps is gaining massive popularity across all industries, including manufacturing.

- Streamlined communication and increased collaboration define DevOps adoption as significant in manufacturing.

- DevOps enables manufacturing companies to transform their operations from production efficiency to product customization while improving speed to market, efficiency, and agility.

- Veritis can help you adopt DevOps phased without committing significant upfront investments.

Conclusion:

While many manufacturing companies have already started experimenting with DevOps adoption, only a few are capturing its full value. Legacy systems, complex processes, and uncoordinated actions by disconnected teams are a few factors undermining even the most strategic approaches. That is why businesses across the world are seeking the help DevOps service providers like Veritis.

With over a decade of presence in the US IT marketplace, Veritis, the Stevie and Globee Business Awards winner, can help you draft the right DevOps strategy focused squarely on business outcomes. We help you start small without the need to commit significant upfront investments and adopt DevOps practices in a phased manner. Get in touch with us today to jumpstart your DevOps journey.

Additional Resources:

- Waterfall Vs. Agile Vs. DevOps- Which Production Method Should You Take?

- DevOps for AI: Make AI Operationalization a Core Business Objective!

- DevOps Market To Be Worth USD 17 Billion By 2026!

- DevOps Implementation: 4 Steps to Success

- 10 Ways AI is Transforming DevOps

- A Guide to DevOps Implementation on Google Cloud